Thermal power plant situated in Ghorashal Bangladesh is one of its kind in the region, we are proud to be the part of rebuilding the infrastructure.

Introduction

Thermal Power plant dictates the notion of greatness and pride of Bangladesh power industry, it is an honour for the entire Bark team to become an integral Mega power plant.

Thermal energy is the primary source of energy for Bangladesh, it is not just important that the time consumed while repairing the plants, rather it is an absolute necessaity.

The marvelous antique infrastructure gave us the right platform to work and mobilise the what was remaining of it. The structure was old and required severe greasing, repairment and modification, however, we worked fine and on point while rebuilding the structure from its scratch. Congrats to our team

Ariful Islam, Operation Director

Environment and Thermal Energy, we kept both of that in mind.

We Kept everything in mind, Including the intruging environment issue, Below was the script everyone had to read and then do their research before coming into work

Thermal power stations

Thermal power stations are facilities in which the energy content of an energy carrier, i.e., a fuel, can be converted into either electricity or electricity and heat. The type of power plant employed depends on thesource of energy and the type of energy being produced. Possible energy sources include: – fossil fuels such as coal, petroleum products and natural gas – residual and waste materials such as domestic and industrial refuse and fuel made from recovered oil – fissionable material Thermal power plants can be designed for different fuel sectors in the interest of greater fueling flexibility and/or higher efficiency - one example being a combination power plant with a gas turbine running on natural gas and an oil- or coal-fired steam generator feeding a steam turbine. Renewable sources of energy such as wood and other forms of biomass are not dealt with here, as they are the subject of a separate environmental brief. Nuclear thermal power plants have also been omitted from this catalogue. The frame of reference concentrates extensively on fossil-fueled power plants, in particular types using coal and petroleum products, the present and near-future use of which is of eminent importance in most developing countries. With regard to hydropower, the reader is referred to the environmental brief Large-scale Hydraulic Engineering. As far as the form of energy being generated is concerned, there are three main types of thermal power stations: – condensing power plants used exclusively for generating electricity – steam- or hot-water producing heating stations for domestic or industrial purposes – district heating power stations, or cogenerating plants, for the simultaneous generation of electricity and available heat. It is important to note that, for economic reasons, process heat and heat for heating purposes should only be generated in close proximity to the users. For thermal outputs ranging from 50 to 100 MW, the distancebetween the power plant and the user should not exceed 2 to 5 km. Conversely, electricity can be economically transmitted over very substantial distances; cf. environmental brief Power Transmission and Distribution. The unit power ratings of fossil-fueled thermal power plants range from a few hundred kW (diesel stations) to more than 1000 MW (oil- and coal-fired stations). In many countries, preference is given to unit ratings of 200 - 300 MWel with deference to power system stability. The better the boundary conditions, the higher the achievable capacities.

2. Environmental impacts and protective measures

The environmental consequences of any given plant are both plant- and site-dependent. Thermal power stations can impact the environment in different ways and at different locations. A typical thermal power plant is likely to comprise the following principal components:

– facilities for preparing and storing working materials

– facilities for burning fuel and generating steam

– facilities for generating electricity and available heat

– facilities for treating exhaust gases and solid and liquid residues

- cooling facilities

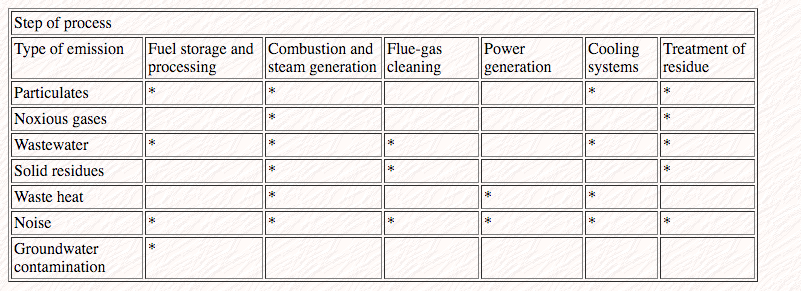

Table 1 surveys the potential emissions occurring at different stages of the generating process:

The main environmentally relevant effects of a thermal power plant derive from the combustion process and its particulate and gaseous emissions. As a rule of thumb, the environmental impacts of thermal power plants, i.e., pollution, spatial requirements and residues, tend to increase in severity for gas, light fuel oil, heavy fuel oil and coal, in that order.

Prior to examining the environmental consequences and possible protective measures for the various domains, let us begin with a few basic introductory remarks. The running text contains information essential to the subject environmental consequences and protective measures, while the relevant technical measures are detailed in the appendix.

In addressing the environmental consequences of a thermal power plant, distinction is drawn between emissions, i.e., the release of pollutants from various parts of the plant, the smokestack in particular, andimmissions, i.e., the actual environmental effects of the pollutants, normally referred to ground level - as indicated by the terms "ground level concentration/pollution" and "ambient air quality concentration/standards". Emissions and immissions are interlinked by a number of factors, e.g., plant-specific technical parameters (emission volumes, outlet velocity, temperature), meteorological factors(weather category, wind speed) and range-specific data (distance between the emitter and the ground-level pollution point). Parameters belonging to the first and last categories, e.g., height of stack and distance from residential areas, are more or less freely selectable for new power plants, while the actuating variables for existing plants all belong to the first category. According to the laws of physics (conservation of matter), practically all noxious emissions with the notable exception of CO2, for example, eventually fall to earth. The height of the smokestack, the outlet velocity of the exhaust, and the prevailing wind velocity determine the size of area that will be affected. From a technical standpoint, it is relatively easy to reduce ground-level concentrations for a given area by increasing the height of the smokestack. Since, however, the specificemission volume does not change, but is simply distributed over a wider area, the extent to which such a measure would aggravate the environmental impact outside of the subject area would have to be clarified.

Measures aimed at reducing the environmental consequences of thermal power plants can be categorized as follows:

- alteration of boundary conditions

• incentives for the efficient utilization and conservation of energy, e.g., cost-covering power rates and taxes

• appropriate siting

- nontechnical protective measures

• regulations dictating the mandatory use of piped energy (district heating) in congested urban areas

• compensation models for the replacement of major emitters

- technical protective measures

• reduction of ground-level concentration, e.g., by extending the height of the smokestack

• emission-reducing measures

* pollution-control measures to prevent or reduce pollution by combustion modification, e.g., choice of an appropriate low-impact fuel such as natural gas (in place of coal), homogenization of fuel to avoid peak emissions, efficiency-enhancing measures, and NOx limitation by combustion engineering measures

* post-combustion measures, i.e., flue gas clean-up.

The order in which the protective measures are taken is subject to the principle of attaching priority to avoidance or reduction over subsequent rectification. First of all, pollution-control measures must be taken topreclude, or at least minimize, the occurrence of pollutants, before any further-reaching post-combustion technical remedial processes are initiated.

One very important relevant measure is to achieve higher efficiency, e.g., by erecting combination power plants or opting for the combined generation of heat and power (cogeneration) in efficient heating power stations with an accordingly low specific pollution level. High efficiency is also the most effective way to reduce CO2 emissions and, hence, their greenhouse effect. For additional means of reducing CO2 emissions, e.g., through the use of renewable sources of energy for power generation, cf. the brief Renewable Sources of Energy.

With regard to environmental consequences, distinction is made between direct consequences, e.g., the emission of pollutants, and indirect consequences such as the transfer of pollutants from the atmosphere to water via scrubbing processes (assuming that the liquid effluent is not subsequently processed) or the environmental impact of limestone mining and attendant road traffic, e.g., the transfer of limestone by truck from the mine to the power plant. Moreover, consequential problems can arise, e.g., the need to properly dispose of the gypsum resulting from flue-gas desulfurization processes (FGD).

The environmental consequences and potential protective measures applicable to the aforementioned areas are explained below.

2.1 Air

The particulate and noxious gas emissions from thermal power plants primarily and directly pollute the air.

Eventually, the particulate emissions and, for the most part, the noxious gases and any atmospheric transformation products that may have formed (e.g., NO2 and nitrate from NO) fall to earth either by way ofprecipitation or dry deposition, thereby imposing a burden on the water and/or soil, with resultant potential damage to flora and fauna.

Depending on the fuel employed (type, composition, calorific value) and the type of combustion (e.g., dry or slag-tap firing), given amounts of pollutants (particulates, heavy metals, SOx, NOx, CO, CO2, HCl, HF, organic compounds) become entrained in the exhaust gases. Table 2 shows the potential concentration ranges of different emissions for various fuels in facilities devoid of flue-gas emission control measures.

The lesser part of the NOx concentrations derives from the nitrogen content of the fuel (fuel NOx). The major share results from the oxidation of atmospheric nitrogen at combustion temperatures exceeding 1200°C (thermal NOx). Consequently, high combustion temperatures go hand in hand with relatively high NOx emission levels. Appropriate combustion engineering measures that are

relatively inexpensive for new plants can keep the emissions at the lower end of the respective range. However, care must be taken to ensure that a high quality of combustion is maintained. Otherwise, excessive combustion engineering measures aimed at reducing NOx emissions could result in a disproportionate increase in other emissions, e.g., carbon monoxide and combustible (unburned) hydrocarbons.

In general, CO2 emissions are mainly limited by controlling the burnout process such as to minimize the discharge of CO and the escape of combustible hydrocarbons. Unlike particulates, SO2, NOx and halogen compounds, CO and combustible hydrocarbons effectively defy retentive measures. Combustible hydrocarbons in particular include numerous chemical substances that can cause toxicological problems, e.g. benzpyrene.

Plants fueled with coal or heavy fuel oil also emit small amounts of hydrogen chloride and hydrofluoric acid (HCl and HF) ranging from 50 to 300 mg/m³STP. As a rule, the concentrations stay well below the SO2levels and respond favorably to desulfurization processes, by which they are reduced even more than S2.

There are many combustion-stage and post-combustion alternatives for use in reducing air pollution from thermal power plants. Appendix A-2, for example, sketches out an integral set of DeNOx, particulate-control and desulfurization measures for the flue gas of a steam generating facility. The various measures are individually described in the following subsections.

2.1.1 Dust control

Dust control for power plants can be based on ordinary and multiple cyclone separators and electrostatic precipitators or fabric filters - with the order of mention corresponding to their respective separation efficiencies: from 60 % - 70 % for cyclone separators to >99 % for electrostatic precipitators and fabric filters. To be sure, the cost of the various options rises disproportionately for increasing separation efficiency. The separation efficiency of electrostatic filters depends on the number of consecutive fields. Like fabric filters, they can achieve extremely low residual emission levels, i.e., about 50 and 30 mg/m³STP, respectively. The drawback of cyclone separators is that they tend to eliminate coarse particles much more efficiently than respirable - and, hence, toxicologically critical - microparticles. Fabric filters are very good at separating out fine dust and its accumulated heavy metals. The capital outlay for flue-gas dust control depends on such parameters as the type of fuel, the required separation efficiency and the technique employed. As a rule, the initial cost ranges from 20 to 70 DM/kWel, while the operating expenses amount to 0.1 - 0.6 DM/MWh. The high-ash fuels used in some countries makes flue-gas dust control a difficult problem - including the proper disposal of the dust yield, either by recycling it in, say, building materials, or by depositing it in a landfill. Certain characteristics of the fly ash may require the use of additives to obtain a solidified product that is less susceptible to leaching, this with a view to preventing groundwater contamination.

2.1.2 Desulfurization

SOx from combustion plants can be reduced either by combustion modification measures (use of low-sulfur fuel, direct desulfurization in the furnace, dry-additive method) or by post-combustion clean-up measuressuch as extracting the SOx from the flue gas. The use of low-sulfur fuels is frequently precluded by economic considerations. In each case, the lowest total-cost concept must be ascertained. For example, while the use of a low-sulfur fuel may increase the cost of operation, it could save the cost of installing and operating desulfurization equipment, thus yielding lower overall costs for the power station. Of course, such considerations must also account for other criteria, e.g., using indigenous fuels in order to assure their safe supply. Like solid fuels, sulfurous petroleum products are also amenable to pre- and post-combustion measures. The pollution-control measure of choice is to hydrate the sulfur by adding hydrogen in order to extract the product from the oil, e.g., as vacuum gas oil or a remanent of atmospheric or vacuum distillation. Such processes are only cost-efficient for large capacities and therefore only feasible for oil refinery applications. In athermal power station, the appropriate measures for reducing SOx emissions are restricted to the use of a low-sulfur petroleum product, mixing different fuels and, primarily, flue-gas desulfurization according to the same principle as that employed in solid-fueled facilities (described below and in Appendix A-3). For coal-fired power plants, particularly in response to the pronounced compositional variance observed in the indigenous coals of many countries, appropriate mixing and homogenization can have the positive effect of lowering the peak-value extremes that have to be accounted for in the design of desulfurization systems. Consequently, major importance must be attached to a conscientious analysis of the calorific values and the water, ash and sulfur contents of fuel deriving from, say, different sections of a coal mine. It is also important to ascertain the possible extent of spontaneous desulfurization attributable to the presence of calcium compounds in the coal. Coal can be desulfurized directly at the mine or pit as part of a process in which sulfur and various inert constituents are extracted primarily by wet methods. Depending on the type of coal and on the kind of sulfur linkage, the sulfur content of the coal (glance coal in particular) can be reduced by 5 % to 80 %. No such conditioning measures, however, can reduce the organosulfur content. Sulfite in the form of pyrite (FeS2) can be separated out if it is freely present in the raw coal or is so coarse-grained in intergrowths that it becomes amenable to removal following crushing. Direct in-boiler desulfurization is applied to solid fuels in fluidized-bed combustion systems. Separation efficiencies of 80 % to 90 % are achievable. Dry additive techniques remove between 60 % and 80 % of the sulfur from coal (cf. Appendix A-3 for details). Flue-gas desulfurization techniques enable SO2 separation efficiency levels of 90 - 95 %. Since flue-gas desulfurization equipment is expensive to install and operate, it is more judicious in some cases to install acomponent-flow desulfurization system in which only part of the flue gases are desulfurized, while the remaining, undesulfurized flue gases can be used for heating the treated gases. Of all the described alternatives, flue-gas desulfurization is the most expensive and elaborate. In each case, particularly for retrofitting projects, the spatial integration options must be carefully investigated in advance. A comparison of the aforementioned pre- and post-combustion desulfurization measures shows that the former offer the lower separation efficiencies, but are also less expensive and more conducive to retrofitting. Fluidized-bed combustion, however, is an exception to the rule, as it can only be implemented in new facilities (maximum capacity of commercial-scale systems to date: 150 MWel). All methods of desulfurization and dust control involve the consequential problem of properly recycling or disposing of the residues and, possibly, of wastewater resulting from operation of the equipment (cf. section 2.3). Depending on the size of the plant, the process employed, the separation efficiency achieved, and other factors, the investment cost of a desulfurization system can amount to anywhere from roughly 30 to 550 DM/kWel. Also the increase of auxiliary power consumption to run the system is unavoidable. Dry-additive methods are the least expensive, while regenerative techniques producing compounds of sulfur as their end product are the most costly. The various desulfurization processes also and incidentally precipitate halogen compounds such as HCl and HF even more efficiently than sulfur.

2.1.3 De NOx

The available means of nitrogen removal also comprise pre- and post-combustion alternatives. With regard to sulfur content, a careful choice of fuel can do much to limit NOx emissions. On the other hand, the NOx formation process is more complicated than the conversion of fuel sulfur into SO2, as described in section 2.1. The combustion modification measures aim to reduce the rate of NOx formation during the combustion process, essentially by lowering the maximum temperature of combustion. This can be achieved by design measures, e.g., the combustion-chamber geometry, burner design and configuration, staged air supply, reduced excess air, and such operational measures as reduced combustion-air-preheating temperature or the use of low-nitrogen fuel. The post-combustion DeNOx measures are concerned with reducing the exhaust-side NOx emissions by various means designed to remove the NOx either alone or together with SOx. The only process to have gained commercial-scale acceptance to date is the selective catalytic reduction of NOx (SCR method). In this process, ammonia (NH3) reacts with NOx in a catalytic converter to form water and nitrogen. The process therefore produces no residues (like those from dust-control and desulfurization processes) that would require subsequent disposal. The SCR process takes place at temperatures of 300 - 400°C and can be integrated either on the raw-gas end, e.g., upstream of the air preheater (SCR (ρ) economizer) or on the clean-gas end behind a desulfurizing system (SCR (ρ) FGD). SCR-base processes achieve NOx separation efficiencies of approximately 80 - 90%. Another approach that is particularly well-suited for relatively low separation efficiencies of about 60 % or less is the SNCR process (selective non-catalytic reduction), in which NOx reduction is achieved by spraying ammonia into the boiler at a temperature of some 1000°C. The initial cost of flue-gas DeNOx equipment depends on the size of the plant, the required separation efficiency, configuration, etc. and ranges from roughly 120 to 250 DM/kWel.

2.1.4 Greenhouse effect

The greenhouse effect, i.e., the long-term warming of the earth's atmosphere due to the presence of anthropogenic trace gases, is chiefly attributable to the accumulation of gases such as carbon dioxide (CO2),methane (CH4), chlorinated fluorocarbons (CFCs), tropospheric ozone (O3) and nitrous oxide (N2O) - with the order of mention corresponding to the relevant significance of the gases. Their specific contributions to the greenhouse effect are widely variant. Methane, for example, has roughly 21 times the effect of CO2, but occurs globally in much smaller mass volumes than does CO2 as the end product of any combustion process involving carbonaceous (organic) fuel. The principal protective measure to counter CO2 emissions is to ensure high combustion efficiency, e.g., by way of a combination or cogeneration process. Other measures like the use of renewable sources of energy - hydropower in particular - for generating electricity, in addition to measures aimed at steering the demand for electricity, are very important, but would never suffice to render superfluous the generation of electric power in fossil-fueled thermal power plants.

And many moreee......, but we ensured the best minimum environmental escape. a very successful mission indeed.